portfolio

So what did I do, what did I make? What did I design and am I legally allowed to show you? You'll find some of it on this page, which will be supplemented by the time.

Below are some of the projects I worked on using 3D software such as Solidworks and Keyshot. More projects can be found in the written Mature portfolios.

Development custom parts - WSI Models / Final

concept Bachelor Thesis - WSI Models / Polesie

Netherlands / Final concept Nature wall - Healthcare

Architecture / Final concept supporting arm for the

disabled - Mitoo / Baby pouch for Happy Baby

Products - ET2C / Toothbrush for Accesia - ET2C /

Design radiator housing - Ulamo

-crop-u13311.png?crc=3860930469)

pre-production sample

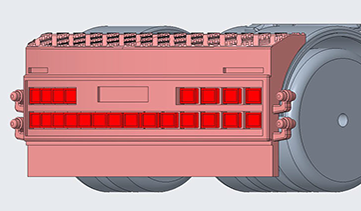

wsi Models - bumper for per andersen

From time to time WSI Models produces scale models for clients which have custom parts on their truck. An example of such order is this one from Per Andersen for which the custom bumper had to be made. As a project manager it is my responsibilty to coordinate the complete development process and make sure the final model looks exactly the same as the real truck.

Normally the 3D files are made by the engineering team but in some occations it occurs these are made by me, If, for example, the design is difficult to explain it is more efficient to make the 3D by myself.

During the Covid-19 pandemic I also worked out some of the custom parts as the engineering team was in lockdown and the urgent orders couldn't wait until the engineers were back in the office.

simplified design of the

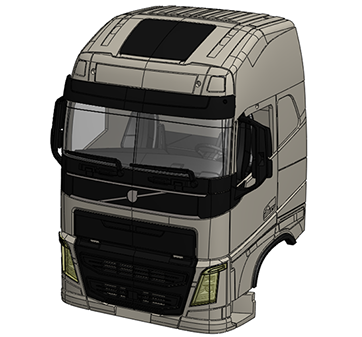

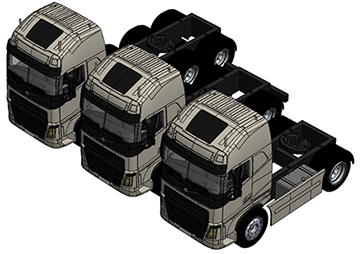

DAF xf and Volvo FH16 Globetrotter

presentation render of final multiwall concept

casing built out of sheet metal

wsi models/polesie netherlands - graduation project product proposal

For my graduation project of Industrial and Product Design education I wrote my bachelor thesis at WSI Models. During this project of six months I worked on a toy truck line for WSI Models, in cooperation with toy company Polesie. As these two companies have a different level of detailing solutions had to be found to serve both WSI as Polesie clients.

For this project three main concept propopals were worked out in Solidworks, which can be seen here. One of the main goals for the toy line was to examine interchangeable cabs, which can be placed on multiple chassis lengths, and implement this idea in a simple way.

The proposals were presented to the clients and based on multiple analysis, such as production costs, the final concept (concept #2, the orange and grey trucks above) have been chosen. After working out this concept more extensively it was handed over to the production engineers at Polesie.

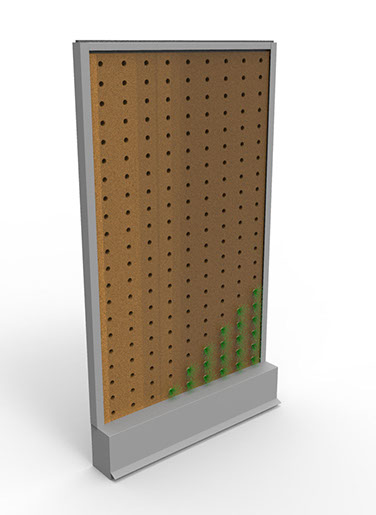

healthcare architecture - Overview multiwall

To finalize the second and final phase of the minor Healthcare Architecture me and my project group converted the results of multiple plant- and healthcare studies into product ideas. The best ones were put into concepts, in which the one above was the best choice based on applicability in housing and office interiors and based on the multifunctionality. This concept is built out of a sheet metal structure and casing and contains a tank which waters the plants from above by use of a water pump.

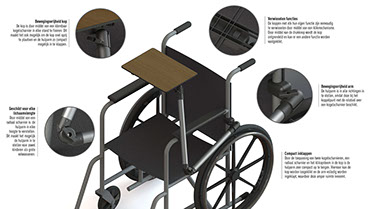

mitoo - supporting arm for the disabled

During my internship at Mitoo I worked on a supporting system for disabled people, which make use of a wheelchair. For this, multiple user-, usage- and market analysis have been done to get to know what this user group needs, how they use similar products and what kind of similar products are available already. Based on the outcomes multiple idea proposals were evaluated and worked out to this final concept, a multifunctial arm with exchangeable heads.

final production sample

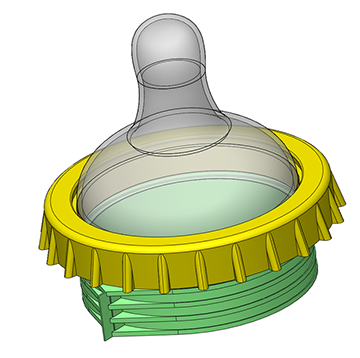

et2c - baby pouch for happy baby products

During my internship at ET2C and thereafter I designed a foldable baby pouch for the company Happy Baby Products. The goal was to come up with a solution to have a baby pouch which could be made smaller when it turned empty. After doing analysis at existing foldable drinking products, a combination between an adult drinking pouch and a classic baby bottle came forward as the best idea.

During the development multiple problems were tackled, such as production capabilities at the current supplier. As this supplier couldn't meet the minimal diameter demanded by the client, I made the decision to reach out to other suppliers. After implementing multiple design and functionality improvements the foldable baby pouch went into production and sales in Asia and Pacific.

For more projects, please take a look at the desktop version!